As an engineer specializing in the fans of the HVAC system. What factors do I need to pay attention to?

- Share

- publisher

- Belinda

- Issue Time

- Sep 4,2025

Summary

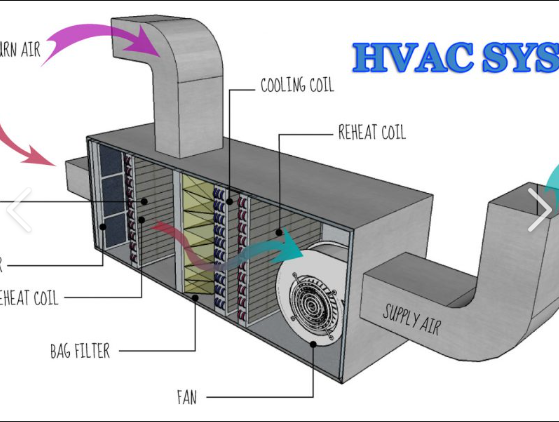

As an engineer specializing in HVAC fans, your focus shifts from purely commercial considerations to the deep technical and application-specific details that ensure optimal system performance, reliability, and efficiency. Here is a comprehensive breakdown of the critical factors you need to engineer and specify.

1. System Design & Performance Point Analysis

This is the core of your responsibility. Selecting a fan is about matching its performance curve to the system curve.

Accurate System Curve Calculation:

Total Static Pressure (TSP): Meticulously calculate the pressure drop through all components: ductwork (including fittings), filters (clean and dirty pressure drop), cooling/heating coils, dampers, sound attenuators, grilles, and diffusers. Always include a safety factor (typically 10-15%) but be reasonable—overestimating leads to oversizing, inefficiency, and noise.

System Curve Plotting: Understand that the system curve is parabolic (∆P ∝ Q²). A small error in flow requirement leads to a larger error in pressure requirement.

Operating Point Selection:

Fan Laws: Master the use of Fan Laws (Affinity Laws) for accurately predicting performance changes with speed, diameter, and density.

Target Operating Point: Select a fan so that the required operating point (Q, P) falls on the fan curve, ideally on the right side of the peak pressure point to avoid instability.

Stability: Avoid selecting a fan that will operate in the "stall" region (left of the peak pressure on the curve), which causes pulsations, vibration, and high noise.

2. Fan Selection & Technology

Fan Type & Class:

Centrifugal:

Airfoil (AF) / Backward Curved (BI): First choice for high-efficiency, clean air applications (AHUs). Non-overloading power characteristic.

Backward Inclined (BI): Robust, high-efficiency, good for a wider range of applications. Less efficient than AF but often more durable against slight particulate.

Forward Curved (FC): Lower speed, quieter, lower cost. Used for lower pressure, lower temperature applications (e.g., residential furnaces, fan coils). Power rises towards free delivery—risk of motor overload.

Radial/Radial Tip: Rugged design for industrial applications, high-pressure, and materials handling (dust, chips). Power constantly rises.

Axial: For high-flow, low-pressure, low-system-resistance applications. Evaluate vaneaxial vs. tubeaxial.

Vaneaxial: Guide vanes recover static pressure, making them more efficient and capable of higher pressures than tubeaxial fans.

Mixed Flow: Ideal when space is constrained, and performance requirements fall between centrifugal and axial.

Drive Type:

Direct Drive: Simpler, more efficient (no drive losses), lower maintenance. Requires a motor rated for the impeller's full speed. The standard for modern EC fans and smaller AC fans.

Belt Drive: Offers flexibility in matching fan speed to requirements by changing sheave sizes. Allows use of standard constant-speed motors. Requires maintenance (belt tensioning, replacement), has energy losses, and needs guarding.

3. Aerodynamic & Mechanical Considerations

Fan Efficiency: Don't just look at peak efficiency. Analyze the efficiency island across the performance curve. The fan should operate within its highest efficiency range at the design point and across expected part-load conditions.

System Effect: This is critical and often overlooked. Account for inadequate inlet ducting and outlet conditions.

Inlet Conditions: Elbows or obstructions too close to the fan inlet create uneven airflow into the impeller, severely reducing performance and increasing noise. Use inlet cones/venturi inlets and ensure adequate straight duct run (3-5 duct diameters if possible).

Outlet Conditions: Sudden expansions right at the fan outlet cause system effect losses. Ensure a gradual expansion or adequate straight run after the fan.

Surge and Stall: Understand the mechanisms. Surging (a system instability) occurs when the system resistance is too high for the fan, causing flow reversal. Stall (an aerodynamic instability) occurs at low flow rates on a given fan curve. Both are destructive and must be avoided.

4. Acoustics (Sound & Vibration)

Sound Power vs. Sound Pressure: Specify and evaluate based on Sound Power Levels (Lw) in octave bands, as this is the inherent noise generated by the fan. Sound Pressure (Lp) is dependent on the room environment.

Breakdown: Analyze the contribution of discrete tones (Blade Pass Frequency - BPF), broadband noise, and specific components (inlet, outlet, casing, motor).

Vibration: Specify acceptable vibration levels per AMCA 204 or ASHRAE standards. Ensure proper balancing (both static and dynamic), isolation (spring isolators, rubber pads), and critical speed analysis to avoid resonance.

5. Materials & Construction

Material Selection: Base this on the airstream properties.

Clean Air: Galvanized steel, aluminum, painted carbon steel.

Corrosive Environments (pools, coastal, chemical): Stainless steel (304, 316), epoxy-coated, or plastic composites.

High Temperature (Smoke Extract): Select materials and bearings rated for the required temperature (e.g., 250°C, 400°C).

Construction Details: Specify casing thickness, access doors for inspection, drain holes, drive guards, and lifting lugs.

6. Motors, Drives & Controls

Motor Types:

AC Induction Motors: Standard, robust, cost-effective. Require a VFD for variable speed.

EC (Electronically Commutated) Motors: Integral brushless DC motor and speed control. High part-load efficiency, built-in controllability, compact size. The future of HVAC fan technology.

Variable Speed Control:

VFDs: Essential for energy savings in variable air volume (VAV) systems. Understand their impact on power quality (harmonics) and motor cooling (cfm/hp derating at low speeds).

Control Strategy: The fan curve shifts with speed per the Fan Laws. Using speed control to reduce flow is vastly more efficient than using inlet guide vanes or discharge dampers.

7. Codes, Standards & Testing

Performance Certification: Always specify AMCA Certified Ratings (Seal). This independent verification ensures the published airflow, pressure, power, and sound data are reliable for your calculations. Key standards:

AMCA 210: Air Performance Testing.

AMCA 300: Sound Testing.

AMCA 205: Energy Efficiency Rating.

Application Standards: Ensure compliance with relevant codes: NFPA (for smoke control), UL (safety), AHRI, and local energy codes (e.g., DOE, ErP) which set minimum efficiency requirements.